- Home

- Products

- Purse Seine

- Seine Nettings

- Ultra Cross Knotless Netting

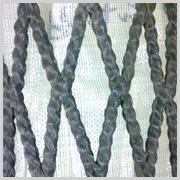

Ultra Cross Knotless Netting

Ultra Cross Knotless Netting

Tenacity Polyethylene, and Nylon or Polyester fiber attributes.

HIGH STRENGTH

Synthetic fibers lose 30 to 60% of their strength when knotted. In Ultra Cross Netting,

fibers are always aligned so 100% twine tenacity is maintained throughout the mesh intersect.

REDUCED DRAG

The aggregate resistance of knots in standard netting is considerable and becomes

an important factor where water flow through the mesh is a concern.

LOW FRICTION, HIGH ABRASION RESISTANCE

Without knots, Ultra Cross Netting does not have high spots to abrade on stern ramps, ship rails,

net rollers, or even rough bottom. In the case of purse seines, the netting shoots very smoothly as there is no inter-knot friction.

LESS BULK and WEIGHT

Less twine is used to make the meshes, which in some cases can mean a savings of 50% of the raw material. Without knots, the bulk of the netting is also reduced. A single layer of Ultra Cross can replace two or three layers of double knotted netting, reducing bulk, weight, and improve the "fishability" of a net.

STABLE MESH SIZE

Knots can tighten or distort throughout the life of netting, dramatically changing mesh size.

Hollow braided twines can hold sediment which not only wears on the twine from the inside,

but also changes mesh size. Ultra Cross Netting maintains nearly 100% of it's original mesh size throughout the life of the product, does not hold sediment because of the 4 strand braiding process, and has no knots to distort.

PERFECT for SQUARE MESH APPLICATIONS

Ultra Cross Netting has proven to be the best material for square mesh and selectivity applications.

The Danish Fisheries Institute, the Institute of Marine Research in Bergen, the National Research Institute of Fisheries in Japan, and many other fishery agencies around the world have endorsed Ultra Cross Knotless Netting as the ideal square mesh material. Ultra Cross is also used where size selectivity is important for onboard mechanized fish handling systems, where a specific size fish is targeted to maximize machine efficiency.

ENDS of STRANDS DO NOT FRAY

The unique four strand construction of Ultra Cross Netting produces a very stable twine.

This twine resists fraying and broken bars do not unravel.

REDUCE DAMAGE to FISH

Ultra Cross Netting is very kind to fish with less bruising and abrasion from knots. This fact has been proven in many of the worlds' fisheries where product quality cannot be compromised.

LESS DISTORTION and TEARING

Distortion and tearing are major concerns in webbing. The four-strand braid construction of Ultra Cross results in a positive lock at strand intersections, virtually eliminating netting distortion and slippage of the intersections. Such a positive lock cannot be obtained with Twisted Cross Netting which utilizes a two-strand twist construction. Because of it's inherent stability and resistance to slipage, Ultra Cross is ideal for mesh size regulated fisheries, and is easy to repair even if a mesh breaks.

REDUCED TOWING and SINKING RESISTANCE

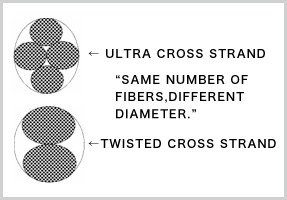

Although utilizing a different number of strands, the total number of fibers used to make the strands for Ultra Cross and Twisted Cross are the same. If each strand of Twisted Cross consisted of 500 fibers, then each strand of Ultra Cross would group 250 fibers. The total number of fibers used to make one two-stranded twist and one four-stranded braid would be 1,000 each.

There is, however, a difference in diameter between a two-stranded twist and a four-stranded braid.

The diameter of a four-stranded Ultra Cross braid is smaller because it is more compact than the bulky two-stranded twist of Twisted Cross netting. A smaller diameter equates to reduced towing and sinking resistance.

Features and Materials

| Features | High mesh strength, no distortion or slippage of the intersections and high abrasion resistance | |||||

|---|---|---|---|---|---|---|

| Materials | polyester, nylon, polyethylene, Dyneema(R) or Vectoran(R) | |||||

* Dyneema(R) is a trademark of Toyobo and Vectoran(R) is a trademark of Kuraray.

Specifications

| Material | Denier | Minimum ply | Maximum ply | Minimum mesh size |

|---|---|---|---|---|

| polyester | 250D | 24 | 800 | 26mm |

| nylon | 210D | 24 | 800 | 26mm |

| polyethylene | 380D | 100 | 800 | 60mm |

| Dyneema(R) | 1,600D | 4 | 120 | 44mm |

| Vectoran(R) | 1,500D | 4 | 120 | 44mm |